Process

step 01

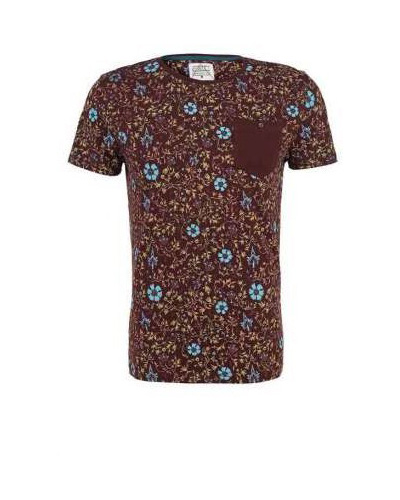

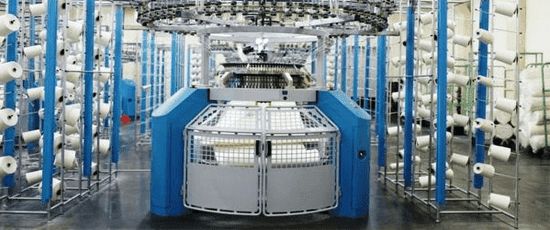

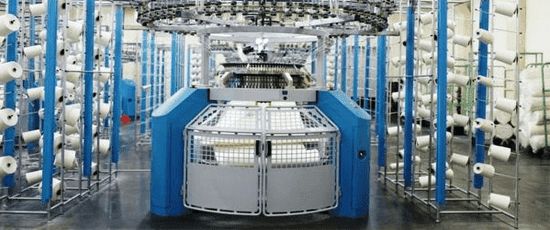

KNITTING

We are operating knitting on overhead basis depending on the requirement, We have modern machines and can manufacture a variety of fabric.

step 02

DYEING

We are using the best available dyeing mills around us after doing complete R & D of the fabric and according to the requirements of the customer. We can process tubular and open fabrics and are also working to technical processing.

step 03

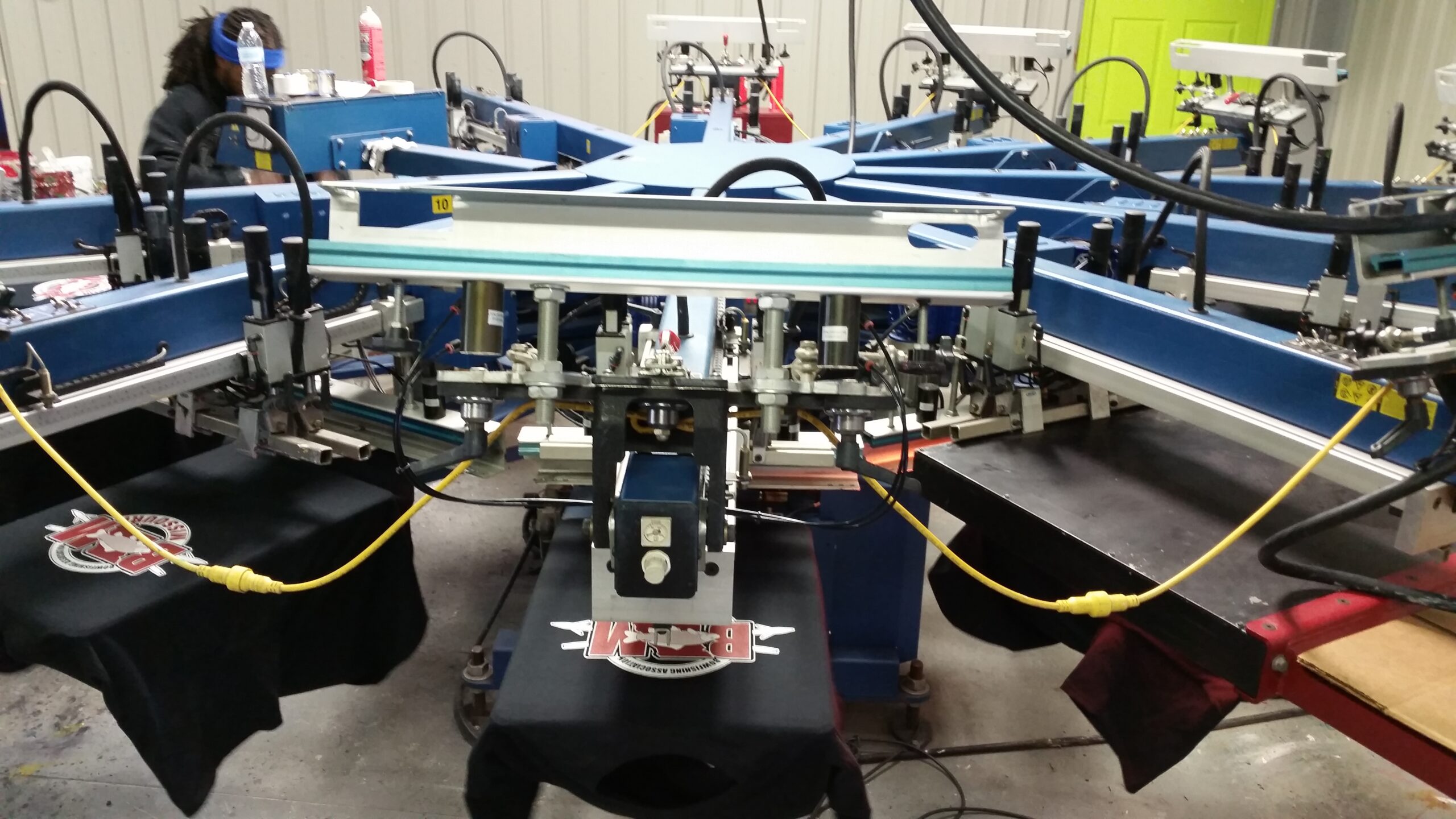

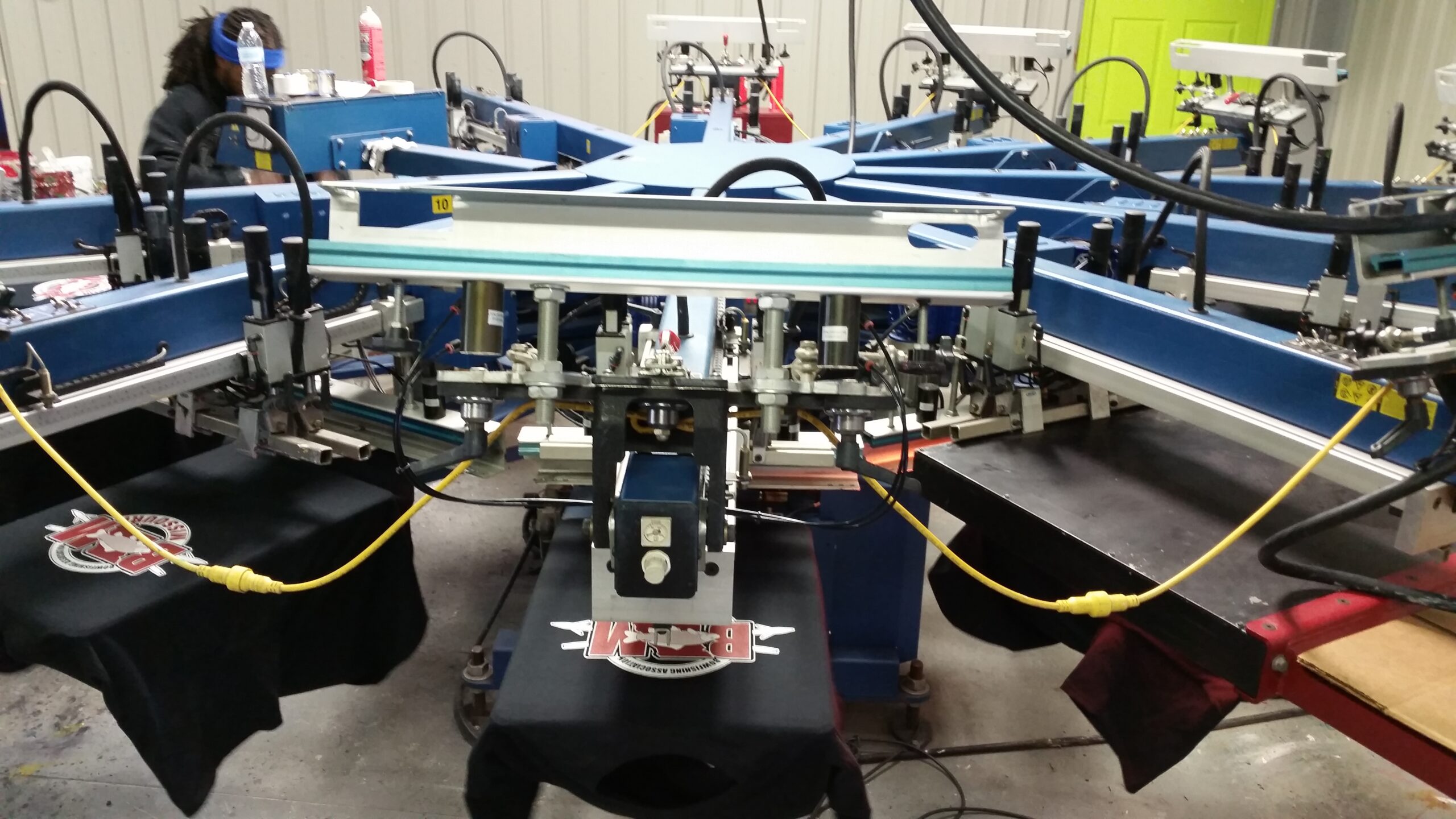

PRINTING

One of the fields of our expertise is screen printing. We print on following fabrics hosiery, denim, jersey, chiffon, cotton, canvas, jacquard, etc. We currently have one semi automatic 12 color screen printing machines, 4 screen printing tables (55 meter long each), 2 infrared dryers and many spot dryers. We deal in all sorts screen printing i.e garment printing. We have printing production of

10000 panels per day.

step 04

STITCHING

We have modern stitching unit comprising of 175 machines capable of producing 4000 – 8000 dozen garments per month and which comprises of latest machines for making apparels. We can work on bulk orders depending on our customer requirement.

step 05

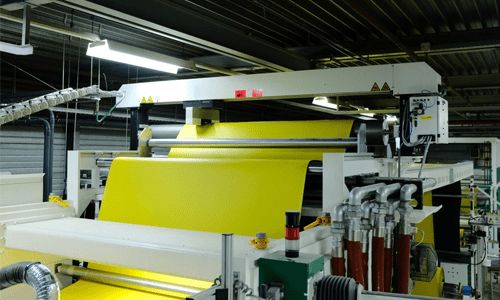

COATING

We also have coating facilities in our premises.

TYPES OF COATING:

1. PU Coating.

2. Acrylic Coating.

3. As per customer requirements.

step 06

FINISHING / PACKING

1. Fire retardant

2. Water replant

3. Stain retardant

4. Wrinkle free finish

5. As per customer requirement.

step 07

MOVE TO PORT

Textile logistics involves the transport and shipping of fabrics and finished garments and products from point A to point B.

step 08

SHIPPING

Package your clothing shipments by first neatly folding the clothing items to comfortably fit inside the bag or corrugated box.